Buyers Guide To Military-Spec Corrosion Inhibitors

By on Jul 15 2013

Many get confused when it comes to deciding what product to use to meet the appropriate application for Mil-C-16173E and Mil-PRF-16173E military specifications. Hopefully this explanation will make it a bit easier. There are four different grades and two different classes that are often used in the military specification for the corrosion inhibitor coatings described above.

Class refers to the percentage of VOC in the coating. Class 1 coatings contain a higher percentage of solvents that will evaporate off the coated surface in order for the coating to dry. Class 2 coatings contain LESS VOC’S and are often stipulated for jobs in or destined to California. If the class is not stipulated in the job specification requirements than you are free to use a CLASS 1 product.

Grades Often the job will require a particular Grade either 1, 2, 3 or 4.

Grade 1 is a black hard drying film for external finished machine parts. Tectyl 891D Class I or Class II

Grade 2 is a SOFT, greasy film that provides undercover protection for metal surfaces on machines, instruments, & bearings. Tectyl 502C Class I or Class II

Grade 3 is an oily film. Water displacing coating used on metal parts. Tectyl 894 Class I or Class II

Grade 4 provides a non-tack, clear surface for general purpose indoor/outdoor protection where handling, stacking or counting is required. Tectyl 846 Class I or Class II

All grades are removable although the method of removal is different for each grade.

For Mil-C-16173E, if there is no mention of the Revision or of the Class number then a revision D product with class 1 is suitable for the job. Example: Mil-C-16173D.

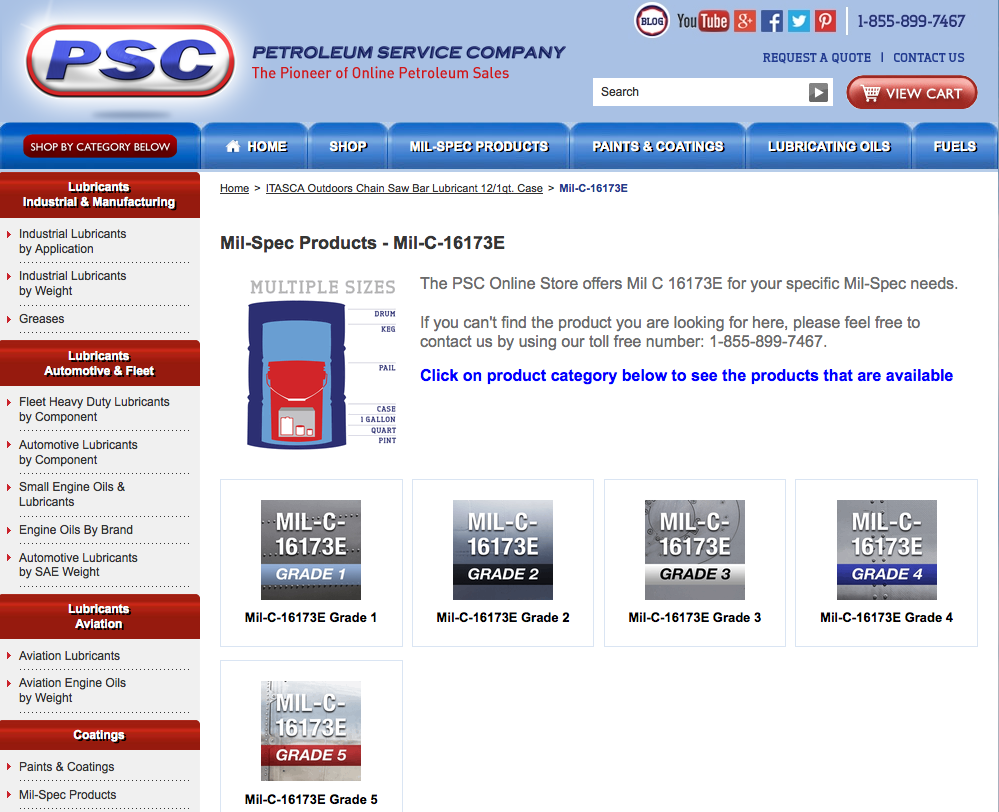

Mil Spec products can be purchased at The PSC Online Store. Please do not hesitate to contact our team of experts with any questions regarding Mil-Spec products.