Top 10 Ways That Shot Peening Improves Quality

By on Feb 24 2015

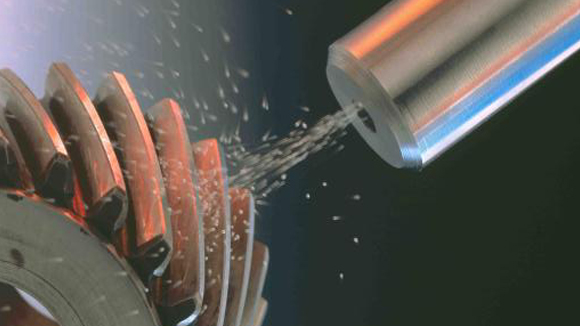

Shot peening is a great way to improve quality in your sandblasting application. It is used on metal parts that are subjected to frequent and repetitive cycle stress, stress reversal, twisting, and torsional stress. The process alters a metal by repeatedly striking its surface with a high-velocity stream of small, spherical media. This could include steel shot, glass beads, ceramics, and more. The media produces round indentations on the surface, causing a stretching of the surface and a rising of the edges of the indentations above the original surface. Complete shot peening creates a compressive stress layer, the depth of which will vary depending on your application. In between surface layers, a tensile layer develops and provides for longer fatigue life of the shot peened coating.

Below are the top 10 shot peening qualities that prove why it is a process utilized by leading industry professionals.

How does shot peening improve quality?

- Increases fatigue life

- Reduces stress corrosion cracking

- Prepares parts for plating

- Straightens parts that were deformed during manufacturing

- Reduces tensile stresses after grinding

- Reveals poor bonding in electroplated parts

- Reduces casting porosity (Fills in porous castings)

- Allows for dimension alterations

- Improves lubricity and oil retention

- Reduces notch sensitivity in high-strength steel