Understanding Grease Flow and Why It Matters in Real Applications

By on Feb 17 2026

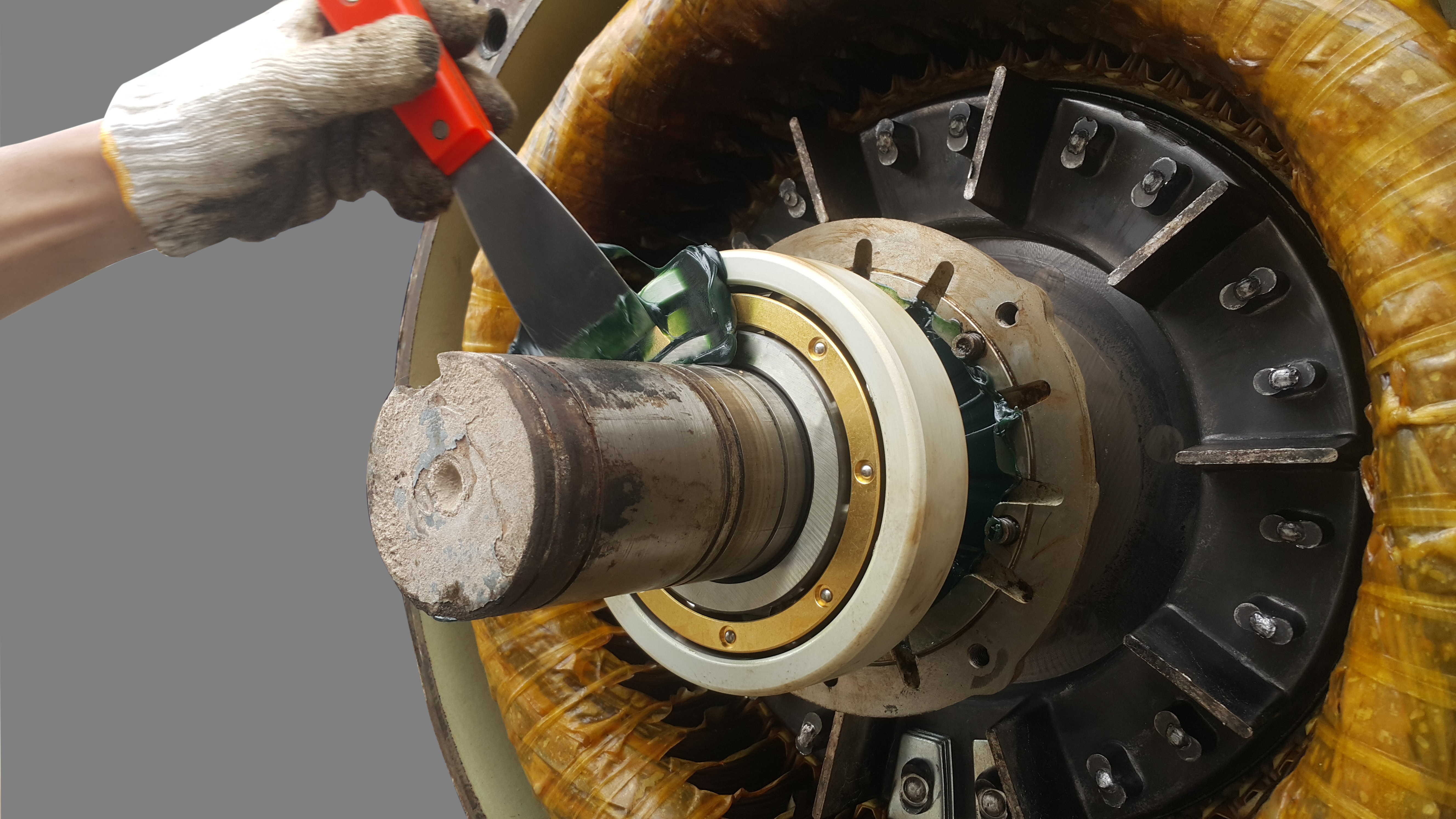

Grease performance is often discussed in terms of wear protection, load carrying ability, and corrosion resistance. Those properties matter, but none of them help if the grease cannot reach the application point. Flow characteristics determine whether a grease can be pumped, distributed, and delivered where it is needed.

Understanding “how grease flows” starts with three core factors. These include base oil viscosity, grease consistency, and how grease responds to applied force. Together, they determine whether a grease works in real operating conditions.

Why Grease Flow Is Critical

A grease that cannot flow cannot lubricate. In centralized systems, poor flow leads to starvation, uneven distribution, and premature component wear.

Flow becomes even more important in cold environments, long feed lines, and automated lubrication systems. Selecting grease without considering flow often results in maintenance issues rather than protection. This is why many heavy-duty and industrial applications rely on greases engineered to balance pumpability with load support, such as Mystik JT-6 Multi-Purpose Grease and Mystik Lithoplex Multi-Purpose Grease, which are designed to move reliably while maintaining film strength.

Base Oil Viscosity and Its Impact

Most grease is oil. It is common for 80 percent or more of a grease formulation to be base oil.

Low-viscosity oils flow more easily and pump better, especially at low temperatures. Higher-viscosity oils provide better load carrying capacity but can become difficult to move as temperatures drop.

As temperature decreases, higher-viscosity oils can thicken dramatically. For applications that demand both high load capacity and reliable flow, greases formulated with heavier base oils, such as Mystik JT-6 Heavy Duty SynBlend 460 Grease, are often selected to provide protection without sacrificing pumpability when conditions allow.

Grease Consistency and Hardness

Grease consistency describes how soft or firm a grease is. Some greases are semi-fluid and can pour from a container.

Semi-fluid greases are often used in cold climates or applications requiring easy flow. At the other end of the spectrum are very firm greases commonly referred to as block or brick greases.

Between those extremes are NLGI Grade 1 and Grade 2 greases, which are commonly used across industrial, automotive, and agricultural equipment. Products like Mystik JT-6 High-Temp Grease #1 and Mystik JT-6 High-Temp Grease #2 illustrate how consistency selection plays a direct role in whether grease stays in place or moves through a system as intended.

Newtonian vs Non-Newtonian Behavior

Fluids fall into two broad categories based on how they react to force. Newtonian fluids maintain the same viscosity regardless of applied stress.

Water, mineral oils, and air are Newtonian. Applying force does not cause them to thicken or thin.

Grease is non-Newtonian. Its viscosity changes as pressure or shear force changes. This behavior allows grease to remain in place at rest while flowing when mechanical force is applied.

How Shear Force Changes Grease Flow

Non-Newtonian materials behave differently depending on stress. Some become thinner under force, while others become thicker.

A common example is ketchup, which flows suddenly after enough force is applied. Another example is a cornstarch and water mixture that becomes solid under pressure and fluid when pressure is removed.

Grease behaves in a similar way. As shear force increases during pumping or movement, grease viscosity changes, allowing it to move through lines and into components. This characteristic is especially important in tacky greases like Mystik Lithoplex Red Tacky Grease, which are designed to resist sling-off while still flowing under load and shear.

Key Takeaways on Grease Flow

Grease flow depends on more than just lubrication properties. Base oil viscosity, consistency, and shear behavior all work together.

Ignoring flow characteristics can lead to poor lubrication, system failures, and increased maintenance. Proper grease selection starts with understanding how grease moves, not just how it protects.

FAQs

Why is grease flow more important than additives?

Additives do not matter if grease cannot reach the lubrication point. Flow determines whether protection is delivered at all.

What makes grease difficult to pump in cold temperatures?

Higher base oil viscosity and firmer grease consistency can cause grease to thicken as temperatures drop, reducing pumpability.

What does non-Newtonian mean for grease?

It means grease changes viscosity as force is applied, allowing it to move under shear while staying in place at rest.

Are semi-fluid greases always better?

No. Semi-fluid greases work well in certain systems, but firmer greases are required in applications needing staying power and resistance to sling-off.

How do I choose the right grease for my system?

Start by evaluating operating temperature, delivery method, and required flow. Then match base oil viscosity and consistency to those conditions.