What Does The ISO VG Number Of A Lubricant Mean?

By on Jul 26 2018

ISO VG stands for “International Standards Organization Viscosity Grade” and is reported in numbers ranging from 2 all the way up to 1500. This number is critical because a lubricant’s viscosity is the single most important factor when selecting the right oil for your machinery.

Being that pieces of equipment are built all over the world, it was necessary to have a standard for equipment users to follow when determining the proper lubrication for that equipment.

So, how is this number determined? Let’s dive in.

Determining the viscosity number

Viscosity is defined as a fluid’s resistance to flow at a specific temperature. In simpler terms, viscosity is a lubricants thickness at a given temperature.

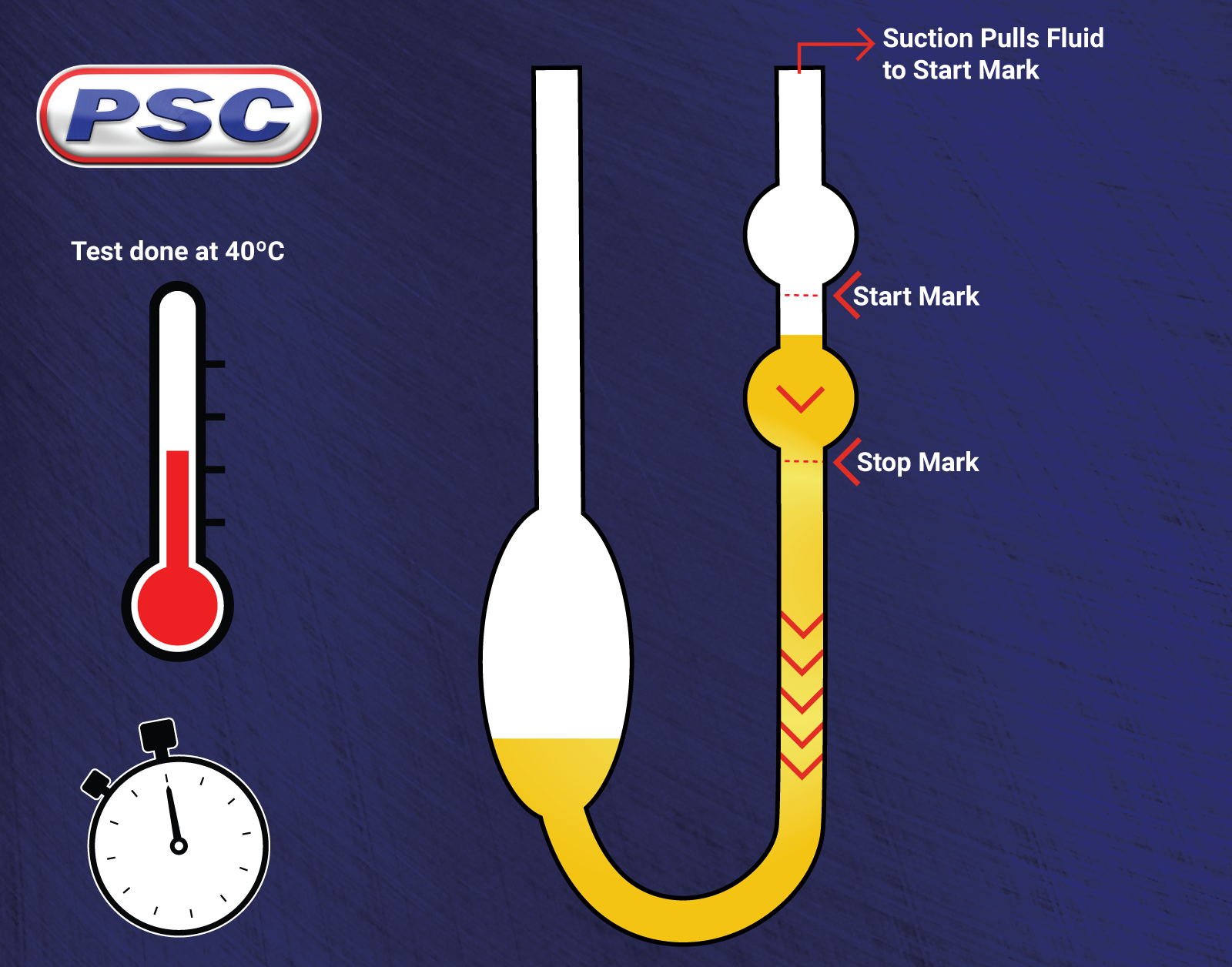

ISO VG is measured through kinematic viscosity, reported in centistokes or cSt, which measures a fluid’s flow under the force of gravity. One of the most common testing apparatuses is the Capillary Tube Viscometer Test. This test is done by placing oil in a glass capillary U-tube and is conducted at a controlled 40°C (104°F). That temperature is considered to be the optimal equipment operating temperature.

In this test, the oil is suctioned to one end of the tube and then released, letting gravity pull it through the tube. The flow time between two marks is then reported in centistokes (cSt) which correlates to an ISO VG number. For example, for a lubricant to be considered an ISO VG “46,” it would have to have a flow speed of 41.4-50.6 cSt.

The thicker the oil (the slower the flow rate) gives it a higher ISO VG number.

Why the ISO VG number is so important

The thickness of the oil between two mating surfaces is crucial for both the longevity of the equipment as well as getting the optimal performance. If the oil is to thin, you will have surface to surface contact, which will create premature wear, friction, and elevated temperatures which leads to oil oxidation. If the oil is to thick it leads to inefficient production, elevated temperatures due to poor heat dispersion, and internal friction.

The ISO VG number is the crucial first step when narrowing down the correct oil for your piece of equipment. It is also just the first step in selecting the optimal lubricant for your operation.

The Original Equipment Manufacturers (OEMs) use these numbers for exactly what they are: standards. That gear box you are trying to lubricate could be used in a completely different environment than another operation using the same gear box on the other side of the world: one could be in 100° heat while the other is below freezing or one could run at the same RPM all day while the other is constant stop and go.

All these conditions can create a need to look beyond the ISO VG standard that is put out by the OEMs. However, being that the oil viscosity is the most important property of the lubricant, it is the best place to start.

This is where we can help. If you’re not sure viscosity of the product you need, our experts are just a call or click away. You can reach out by e-mail at any time or phone at our toll-free number (1-855-899-7467) to speak with our in-house experts.

Alternatively, those same experts created a Cross Reference Tool on our website. Here, you can search for the equivalent of any product. Our tool will pull up all options in all sizes available on our site.

Shop: Industrial Lubricants by ISO VG Weight at Petroleum Service Company

Sources:

https://www.machinerylubrication.com/Read/29451/anatomy-of-viscometer https://www.machinerylubrication.com/Read/411/oil-viscosityhttps://www.britannica.com/science/viscosity#ref166129https://www.sciencedirect.com/topics/chemistry/kinematic-viscosity https://www.machinerylubrication.com/Read/294/absolute-kinematic-viscosity