What Size Compressor is Required for Sandblasting?

By on Aug 20 2014

This is a very common question the staff at SandblastingMachines.com has been receiving. A number of customers and prospective customers have been calling in and asking if their compressor is big enough to run a specific blast pot.

To answer this question we need to pay attention to the nozzle size and not the blast pot itself.

The Blast Pot

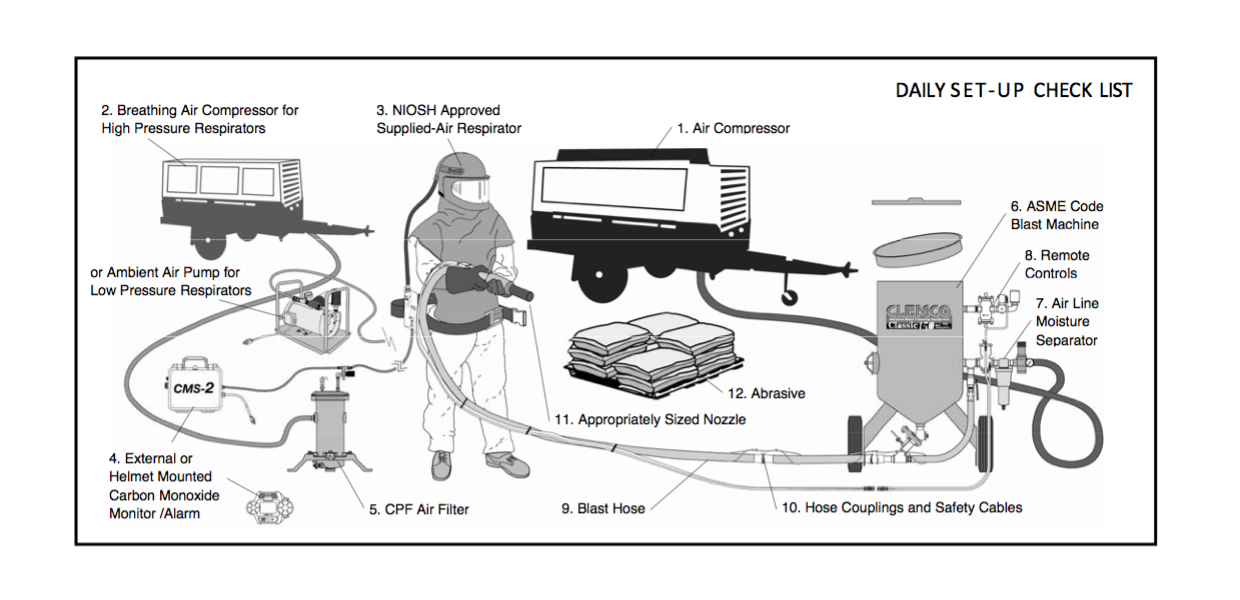

The blast pot itself requires a minimum 50 PSI for the Pop-Up Valve to seal and allow the pot to pressurize. The optimum operating pressure at the pot is 90 PSI to ensure your most efficient and effective blasting. Once pressurized, the compressor needs to have enough air flow to keep the pot at its minimum 50 PSI and still have enough CFM's to allow pressure out at the nozzle. If your compressor can't keep up with the amount of air you are releasing at the nozzle the pop-up valve will unseat and all pressure will be lost.

Another factor to consider is your breathing air respirator. If you are using a high-pressure system an additional 20 -25 CFM's will be needed to supply enough air to the operator. A low-pressure system has its own ambient air pump, so this will not affect the compressor you use.

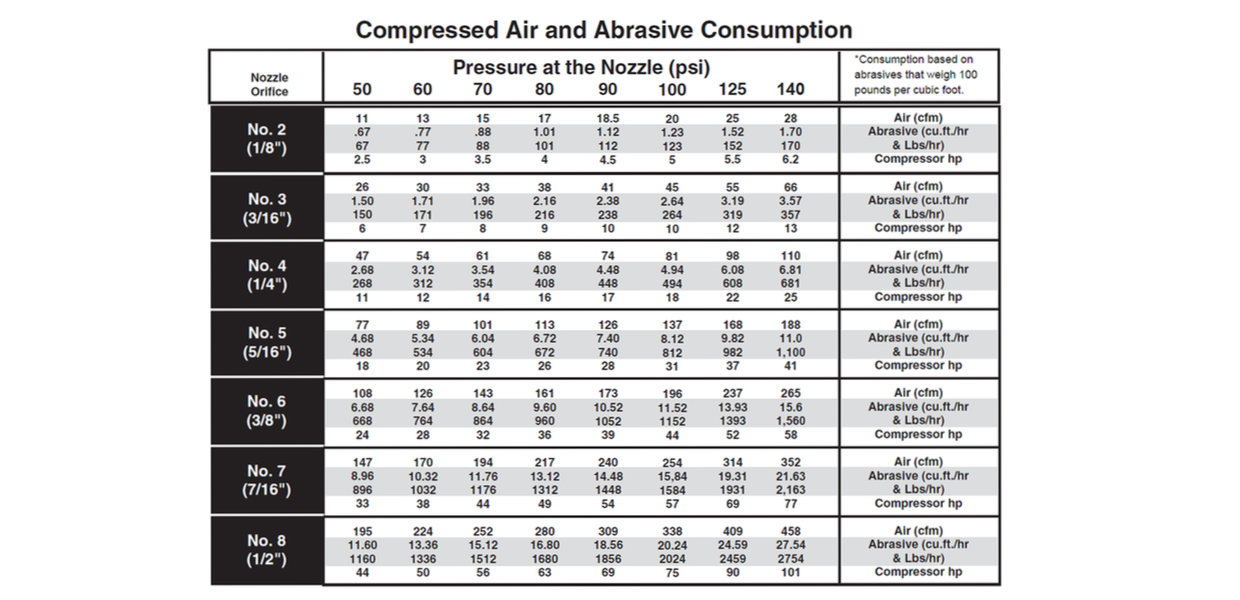

[caption id="attachment_849" align="alignnone" width="1240"] Chart illustrating the compressed air requirements for sandblasting equipment[/caption]

Chart illustrating the compressed air requirements for sandblasting equipment[/caption]

This is an example of a typical blast pot set up. An operator blasting with a Clemco TMP- 5 Nozzle ,5/16 " Orifice, (click here) —at the minimum 50 PSI would need a compressor putting out 77 CFM's. Again, keep in mind that an additional 20-25 CFM's will be required for the High Pressure Breathing Air System (Apollo 600 HP Breathing Air Respirator). This puts you at a total of 97-102 CFM's. If you are blasting with a larger nozzle such as the Clemco TMP-7 Nozzle, 7/16 " Orifice, (click here) —your CFM requirements will increase.

At the minimum 50 PSI a 7/16 " orifice nozzle will require 147 CFM's. As you increase the pressure going into the pot, the amount of CFM's needed at the nozzle will increase as well. The same TMP-7 Nozzle blasting at the optimal 90 PSI will require 240 CFM's to keep up with the amount of air being put out at the nozzle.

If you are in the market for a Clemco Blast pot and are not sure if your compressor is large enough, remember to pay attention to the PSI you are going to be blasting at and the nozzle size you are using.