Comparing Undercoating Application Types

By on May 30 2024

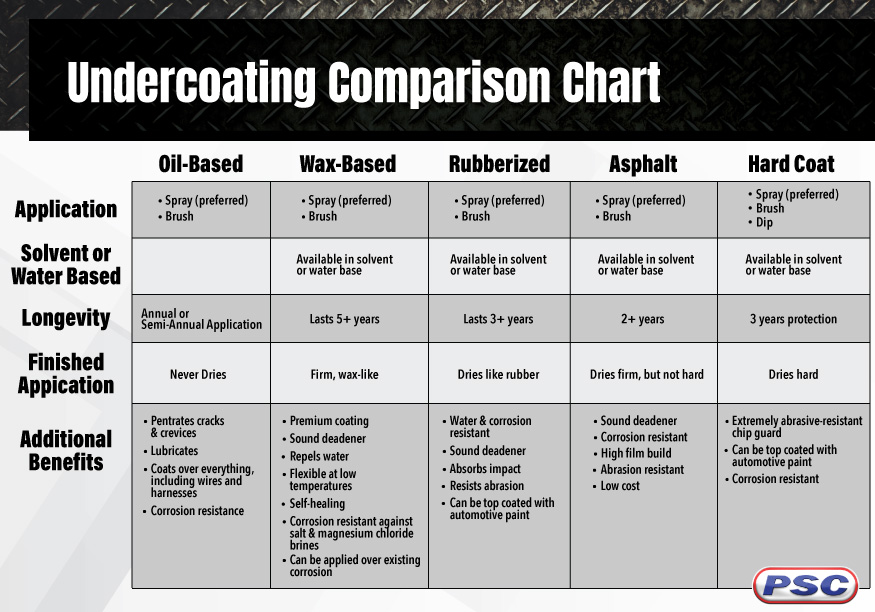

Protecting your equipment from the elements is crucial, and undercoating plays a big role in this. With several options available, understanding their differences will help you pick the best one. Let's break down the key points of oil-based, wax-based, rubberized, asphalt, and hard coat undercoating in a simple way.

Click here to print this chart out

Click the buttons below to learn more about that specific undercoating

Oil-Based Undercoating

Oil-based undercoating is best applied with a spray or brush, with aerosol sprays being the most common and preferred application method. You'll need to reapply this annually or semi-annually since it never fully dries, maintaining its lubricity and penetration. Oil-based coatings are great for lubricating and covering everything, including wires and harnesses. They offer great corrosion resistance, keeping rust at bay.

Wax-Based Undercoating

These can be sprayed or brushed on, with spraying preferred, and come in both solvent and water-based formulas. They can last over 5 years with correct care and preparation, and dry to a firm but flexible, tacky matte finish. Wax-based coatings provide a premium layer that also deadens sound, repels water, and stays flexible in cold temperatures. They're self-healing and resistant to corrosion from salt and chemicals, making them perfect for older equipment with existing rust.

Rubberized Undercoating

Rubberized coatings are easy to apply by spraying or brushing and are available in both solvent and water-based forms. These typically last over 3 years with proper prep and care, and dry to a rubber-like consistency. They offer excellent water and corrosion resistance, act as sound deadeners, absorb impacts, and resist abrasion. Plus, they can be painted over for a polished look.

Asphalt Undercoating

Asphalt undercoating is applied with a spray or brush and comes in both solvent and water-based options. They last around 2 years, drying to a firm, but not overly hard, finish. Asphalt coatings are cost-effective, provide good sound deadening, corrosion resistance, and abrasion protection, making them a solid budget-friendly choice.

Hard Coat Undercoating

Hard coat undercoating can be applied via spray, brush, or dip, and are available in both solvent and water-based forms. They offer up to 3 years of protection and dry to a very hard finish. These provide the toughest protection with excellent abrasion and corrosion resistance. They can be top coated with automotive paint and are ideal for heavy-duty applications.

So, What’s The Right Coating For You?

Choosing the right undercoating depends on what you need. Still not sure which coating is right for you? Watch the video to learn about our easy-to-use Coatings Selector Tool that helps you filter down to find the ideal match for your application. Filter by film type, color, time of protection, coating base, and more.